At Noterd Technology, we specialize in affordable prefilled syringes with rapid global shipping. This guide will help you understand why prefilled syringes matter, how they work, and how we deliver tailored solutions for your needs.

What is a Prefilled Syringe(PFS)?

Prefilled syringes are sterile packaging that holds pre-measured doses of drugs, ready for immediate use. It is designed to save time and nursing costs by allowing pre-loading medication into syringes. This also helps to ensure accuracy when drawing up medications.

Manually filling syringes from vials is time-consuming, prone to dosing errors, and risks contamination. Prefillable syringes could eliminate these risks while cutting preparation time by 50%. They’re ideal for vaccines, dermal fillers, or sensitive biopharmaceuticals—ensuring consistency, safety, and faster workflows.

The prefillable syringes are revolutionizing drug delivery for businesses worldwide.

Types of Prefilled Syringes: Glass vs. Polymer (COC/COP)

Currently, the most commonly used materials for prefilled syringes fall into two main types: glass and polymer. Polymer syringes are further divided into COC and COP varieties. Each type is designed for specific applications, ensuring optimal performance and compatibility.

Here’s a detailed comparison of glass prefilled, COC, and COP syringes. This aims to show the differences for clients choosing suitable prefilled syringes.

Glass prefilled syringe

Material: Type I medical borosilicate glass

Advantages: High thermal/Chemical resistance, Technologically mature, stable production capacity, cost-effective, measurements available

Best For: Vaccines, biologics, and drugs sensitive to interactions.

Limitation: Risk of breakage, heavier than polymer

COC Syringes (Cyclic Olefin Copolymer)

Material: Cyclic Olefin Copolymer

Advantages: lightweight, shatterproof, Low moisture absorption, Excellent clarity

Best For: Sensitive drugs like proteins or hyaluronic acid; Protein-based drugs (e.g., antibodies); Lyophilized (freeze-dried) drugs

Limitation: Higher cost than glass; Limited compatibility with organic solvents; limited production capacity

COP Syringes (Cyclic Olefin Polymer)

Material: Cyclic Olefin Polymer

Advantages: lightweight, shatterproof, Superior moisture barrier properties, Excellent chemical stability, compatible with aggressive drugs

Best For: Peptide-based therapeutics, High-value biologics (e.g., gene therapies)

Limitation: Higher material cost, Fewer qualified manufacturers; Hard for large-scale production

Components of Prefilled Syringes

Prefilled syringes are precision devices built from several critical components. At Noterd, we source components from trusted suppliers like Schott, BD, and West Pharmaceutical Services. Here’s a simple breakdown of how they work.

Sealed System: Luer Lock/Slip Cap

The Luer lock (screw-on cap) or Luer slip (push-on cap) creates an airtight seal with the rubber stopper. This keeps drugs sterile and leak-free. Unlike glass syringes, polymer syringes use a one-piece Luer lock design for durability.

Syringe Barrel and Rubber Stopper

The barrel (glass or polymer) and rubber stopper directly contact the drug, so quality is critical. Whether it is a borosilicate glass barrel or a polymer barrel, both perform well in resisting chemical reactions.

Rubber stoppers are made from bromobutyl or chlorinated butyl rubber for airtight sealing.

Plunger Rods

The plunger rod pushes the drug out of the barrel. Standard plastic rods are clear and practical for most uses. Heat-resistant rods can withstand autoclave sterilization, ideal for hyaluronic acid in beauty products. Custom rods are available for branding or drug differentiation.

Finger Flanges

A finger flange improves grip, reducing slips during injections. Clinics and emergency teams find flanges especially helpful. Many brands use unique flanges with matching push rods for brand image in the market.

By focusing on smart designs and trusted materials, Noterd syringes meet high standards—perfect for pharmaceuticals, cosmetics, and more.

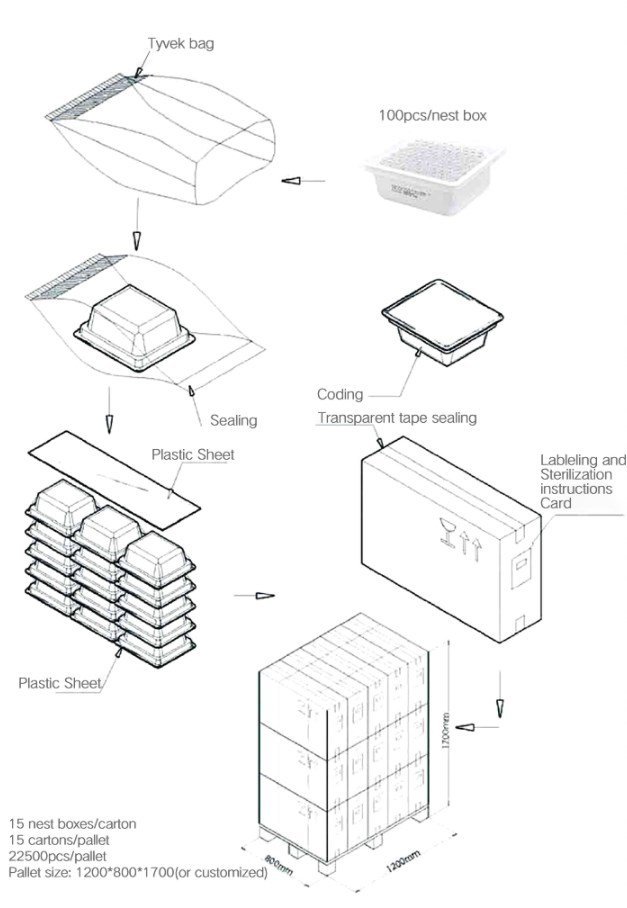

Packaging of prefilled syringe

Glass and polymer prefilled syringes are packaged for safety and sterility. Prefilled syringes of different volumes have different packaging quantities. For instance, syringes with a volume of 1 – 5 ml come 100 in a box. Those with a volume of 5 ml are packed 64 to a box. And syringes with a volume of 10 ml are packed 42 in a box. However, their outer packagings are all the same.

Nest Box Packaging

Every syringe—whether glass or polymer—is assembled with its Luer lock/slip cap and sealed in a sterilized nest box. This standard packaging works with most sterile filling lines globally.

Nest Box Material

The nest box is made of high-polystyrene (PS). This material is eco-friendly, lightweight, and impact-resistant, protecting syringes during long-distance shipping.

Sterile Dialysis Bag

The nest box is wrapped in a specialized medical dialysis bag (like those from DuPont). These bags maintain sterility, ensuring syringes stay contamination-free until use.

Honeycomb Insert

Inside the nest box, a honeycomb insert holds syringes securely in place. Each hole cradles a syringe to prevent movement or damage.

Here is a flowchart illustrating how prefilled syringes are packaged for transport.

The Benefits of Prefilled Syringe

Prefilled syringes are a game-changer in drug delivery. They solve key challenges faced by healthcare providers and businesses. Here’s why they’re better than traditional vials or ampoules:

Less Drug Waste

Expensive drugs, like cancer therapies or rare disease biologics, often stick to the inside of glass vials. This “drug loss” wastes costly medication. Prefilled syringes solve this by minimizing surface contact. For example, a study by NCBI showed prefilled syringes reduce waste by up to 20% for high-value drugs.

Lower Contamination Risk

Every time a vial is opened or a needle is inserted, germs can sneak in. Prefilled syringes come sealed and sterile, no manual mixing or transfers are needed. Think of flu shots—ready to use straight from the package.

Precise Dosing

Machines fill syringes down to the microliter—no human errors. Manual filling (like drawing insulin from a vial) can lead to underdosing or overdosing. Prefilled syringes ensure exact amounts, especially vital for kids’ medications or potent painkillers.

Faster, Easier to Use

Pre-filled syringes cut the time for preparing a dose, which is 2-3 minutes. No filling, no measuring—Just open, inject, and go. Ideal for emergencies (e.g., allergic reactions) or busy clinics.

Choose reliable suppliers of prefilled syringes

Selecting a good supplier of prefilling syringes could boost your business. Here’s a straightforward guide to help you pick the trustworthy partner in China:

When it comes to prefilled syringes in China, Noterd Technology stands out as a trusted partner for businesses worldwide. Here’s why we’re the right choice:

1. FDA DMF Approval

Our syringes meet strict FDA standards. This ensures they are safe and compliant for markets like the U.S. and Europe.

2. Wide Product Range

We offer refillable syringes in all sizes, from 0.5mL to 10mL. You can choose glass or polymer materials to match your needs.

3. Fast Turnaround Time

Most orders ship within 48 hours. This keeps your supply chain running smoothly, even during busy times.

4. Custom Orders & Packaging

Need special colors or customized packaging? We create solutions tailored to your product and market.

5. Global Experience

We’ve shipped to over 30 countries. We know how to handle customs, regulations, and logistics without delays.

6. Quick Response

Our team is always ready to help. We answer questions fast and solve problems quickly within 24 hours.

At Noterd, we focus on quality, speed, and service. Contact us today to see how we can support your business.