Prefilled syringes have transformed modern drug delivery by improving safety, preventing contamination, and simplifying injection workflows.

In pharmaceutical packaging, the term prefilled syringe (empty) is commonly used to describe prefillable syringes supplied sterile and ready for filling, rather than finished drug-filled products.

Noterd is a prefilled syringe supplier specializing in prefillable (empty) syringe systems, supporting pharmaceutical, biotech, vaccine, and aesthetic manufacturers worldwide. As a China-based manufacturer, we focus exclusively on sterile, ready-to-fill syringe packaging, not on finished injectable drugs.

How we got started

In 2004, China lacked the expertise to produce prefillable syringe systems for pharmaceutical packaging. President Gao, the founder of Noterd’s factory, faced a brutal reality: critical machinery had to be imported from Europe, making production slow and expensive. Determined to change this, Gao assembled a small team of five engineers. Their mission is to create China’s first automated molding machine for empty prefilled syringes.

The team worked tirelessly, sketching hundreds of designs. Early prototypes failed, but in 2006, they succeeded. Their first machine could produce 10 million syringes annually, slashing costs and wait times. “We knew innovation was the only way to compete,” Gao recalls. By 2010, our facility had 15 machines and began exporting prefillable syringe packaging to Southeast Asia.

Noterd factory now owns the first complete production lines for prefillable syringes in Asia, and the fourth in the world. We’re also the first enterprise in China to hold a patent for an automatic molding machine dedicated to ready-to-fill syringe manufacturing.

Recent innovations in our production lines

In April 2021, our factory launched the first set of automatic molding machines and needle-filling machines. The equipment has dramatically improved production capacity and quality. The error of 4 wires (0.04 mm) of this gear transmission in German equipment can now reach less than 1 wire (0.01 mm).

We also became the first Chinese enterprise to realize production machine localization, increasing our production capacity from 60 million to 120 million.

The independently developed third-generation equipment has been ahead of Germany’s same equipment. The fourth-generation equipment has also entered the stage of assembly and commissioning. It adopts a new technology that nobody has ever tried in this field. Its process uses big data to collect various gas proportions, pressures, and temperatures of the gas distribution system. It can also automatically adjust.

Our factory has 15 sets of first-generation glass coat molding machines. 7 patents. We have applied for 40 patents for inventions and practical information this year, all focused on empty prefilled syringe systems for pharmaceutical use.

What We Supply (And What We Do Not)

Noterd manufactures and supplies prefillable (empty) syringe systems designed for pharmaceutical and cosmetic filling lines.

✔ Prefillable (empty) syringes supplied sterile

✔ Ready-to-fill syringe systems compatible with automated filling equipment

✔ Glass and polymer (COC / COP) syringe packaging components

✖ We do NOT manufacture or distribute drug-filled syringes

We focus on material control, dimensional precision, sterilization compatibility, and regulatory compliance.

Why prefilled syringe?

The prefilling syringe format allows drugs to be filled directly into the syringe under GMP-controlled production conditions. Compared to the traditional injection vials and ampoule bottles, it ensures zero contact with air during drug use. It also avoids the risk of secondary pollution in the injection process.

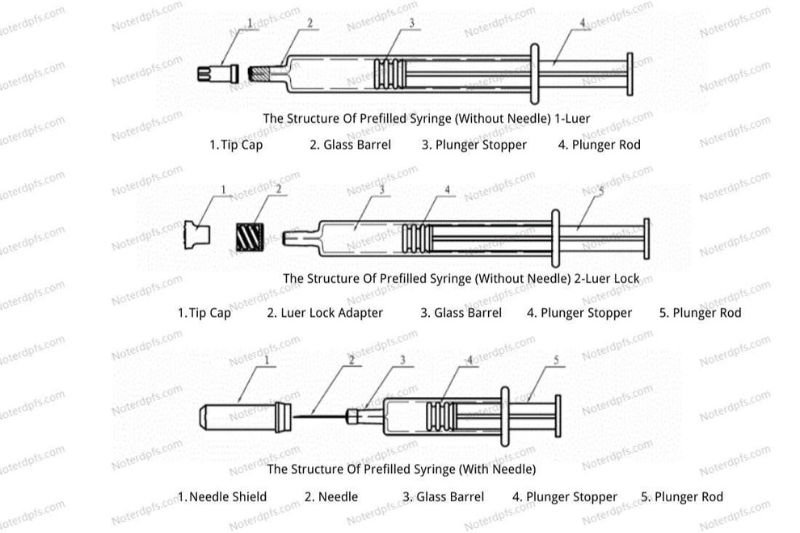

Empty prefilled syringes are widely used as primary packaging for vaccines, biologics, and hyaluronic acid injectables. Glass and polymer syringe systems support various drug types, viscosities, and dosing requirements. Different barrel sizes, plunger designs, and finger flange configurations can be customized to meet specific application needs.

While prefillable syringes are more complex and costly than disposable plastic syringes, their performance, safety, and regulatory advantages justify the investment.

During the COVID-19 pandemic, prefilled syringes proved critical. Stored at -70°C, Pfizer‘s vaccine required packaging that wouldn’t shatter. Glass prefilled syringes, used by regional pharma partners, ensured safe delivery.

Gradually improving prefillable syringe packaging solution

Glass prefillable syringes offer high transparency, excellent chemical resistance, and strong barrier properties. They are prone to breakage and may interact with certain drugs, leading to potential compatibility issues. Then, polymer syringes came into being in response to the need.

Polymer prefillable syringes (COC and COP) are lightweight, shatterproof, and highly customizable in design. They complement glass prefillable syringes by addressing specific needs. Glass & Polymer prefilled syringes provide a comprehensive range of options for drug delivery, catering to diverse patient and medication requirements.

Cooperating with polymer syringe manufacturers in the market, we aim to be the leader in the prefilled (prefillable) syringe industry.

Why are we your best choice to source prefillable syringes?

As a well-known prefilled syringe supplier in China, we have won the trust of many clients with our strength. We always believe that win-win is the foundation of any long-term cooperation. The following are important factors for us to become your partners:

- 10+ years of industry experience. Our professional and efficient service team responds to problems promptly. They help clients match appropriate empty prefilled syringe packaging solutions.

- Most-advanced production lines. Our latest equipment production lines comply with the ISO production system. The GMP workshop ensures high-quality prefilled syringes for pharmaceutical enterprises.

- Premium Partnerships. Our prefilled syringes are made from the secondary processing of neutral glass tubes from Schott and Nipro. The stoppers come from internationally renowned manufacturers such as West and Datwyler.

- Full range of prefillable syringes. We have the most comprehensive range of prefilled syringes, with capacities ranging from 0.5 ml to 10 ml. COC and COP polymer syringes are also available.

- Short lead time. We can adjust production lines quickly based on order requirements. As a result, the average order cycle for regular specification syringes is one week.

- Competitive pricing. With a mature supply chain system, we keep our production costs at a relatively low level. Without brand premiums, our syringe prices remain at a reasonable level.

- DDP term services. Customers only need to focus on the orders themselves. Everything else can be entrusted to us. Our professional transportation services can perfectly integrate with customers’ production processes.